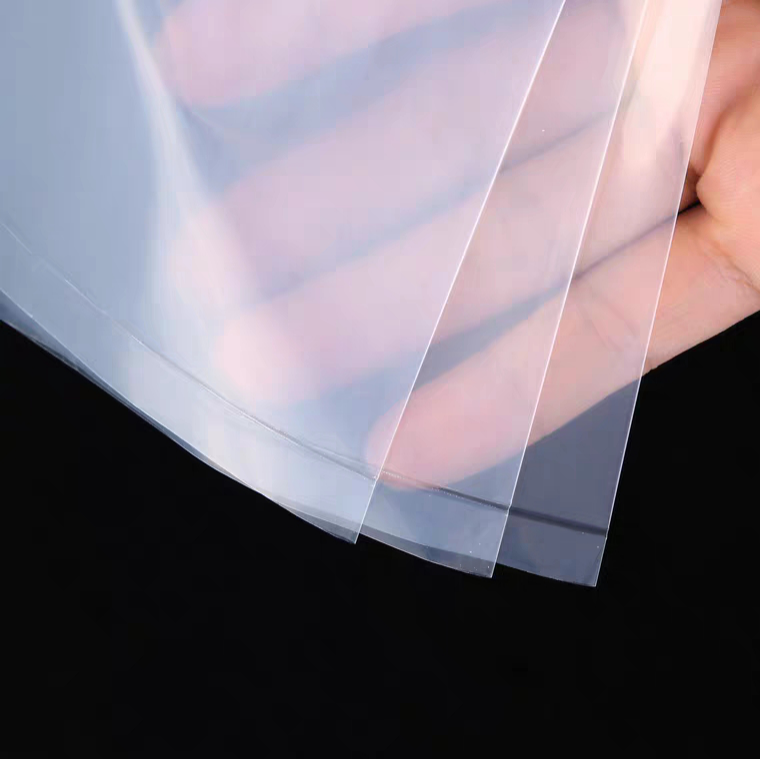

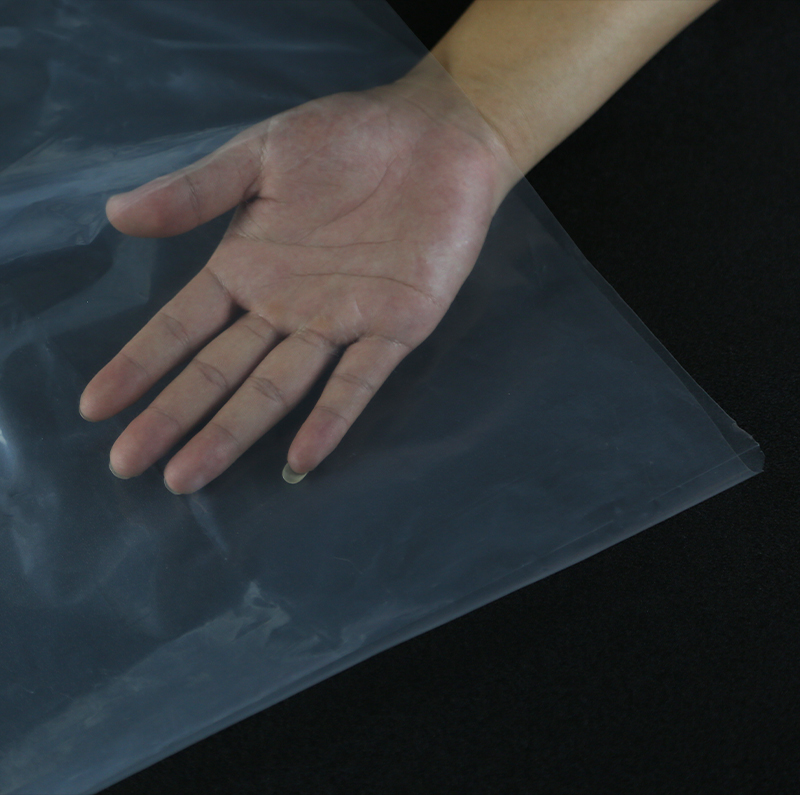

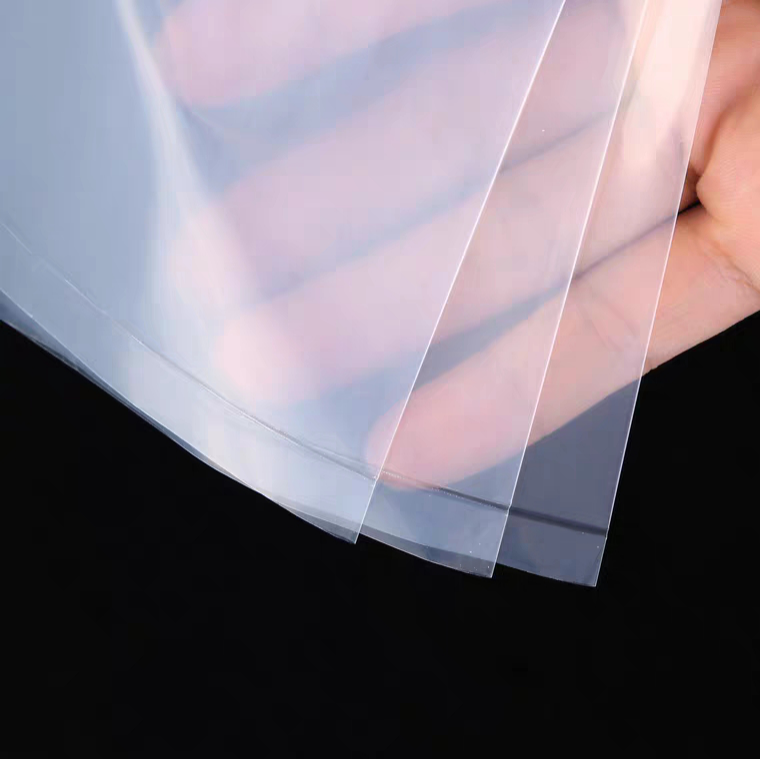

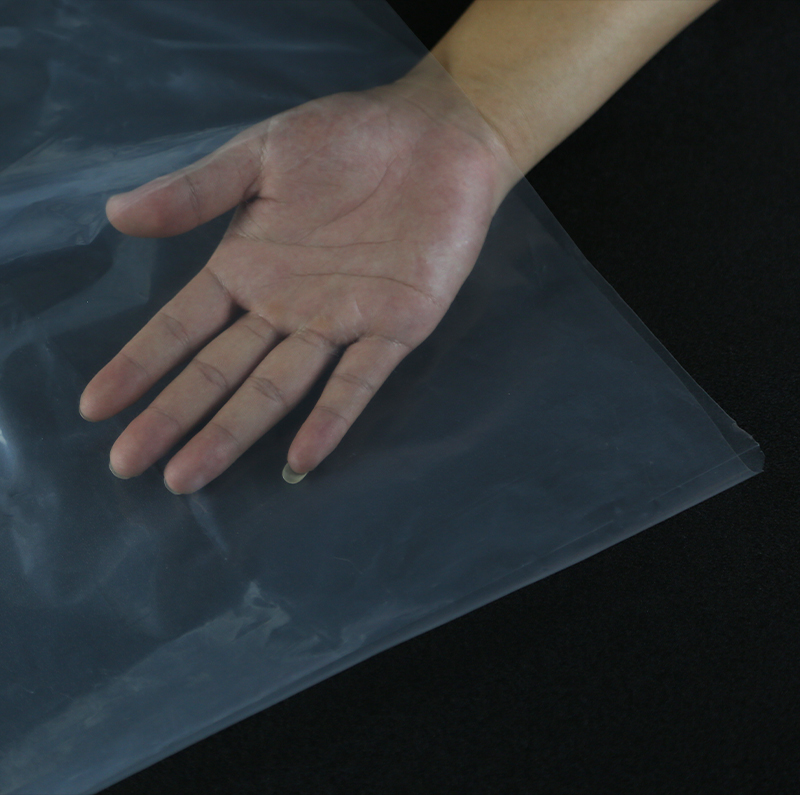

Product Name: PE Potter bag

Material: Low Density Polyethylene (LDPE)

Features: moisture-proof, sealing, transparent, mesh, anti-static

Uses: Electronic products, kitchen, food, crafts, clothing, etc.

The PE bag is formed by a new LDPE (low density polyethylene) raw material blow molding, through the bottom of the bag, the bottom of the bag, the side sealing, according to the production process: PE flat pocket, clip bag, envelope bag, punching Tote bag, hand bag, self-sealing bag.

1, PE flat bag is the simplest production process, after blowing the film by the machine, then cut into the bag, the bottom is sealed.

2, the self-sealing bag is a bone strip by the machine blown film, can be handed manually. Unlike the clip chain bag, the two bags are generally confused.

3, the clip bag is made from the PE film, plus 2 clamps (this clamp is separate), and the bag is generally a relatively wide indentation on both sides, and the self-sealing bag is not. Self-sealing bag printing has little colors, and the clamp bag can be printed with complex patterns.

4, the envelope bag is like a tongue like an envelope, and a strip is posted on the tongue, and the bag can be sealed. The general apparel is used. There is also a courier bag. It is also one of the envelope bag.

5. The punched tote is a hole in proper position at the top of the flat bag to make it easier to make the bag.

6, the handbag is to add a plastic film in the top of the bag, which is convenient for the bag, which is labor-consuming, and the cost is relatively high.

7, the zipper is to install the zipper in the bag seal and bring the zipper cap.

Blown film workshop

PE cutting bag workshop

Self-sealing bag blown film workshop