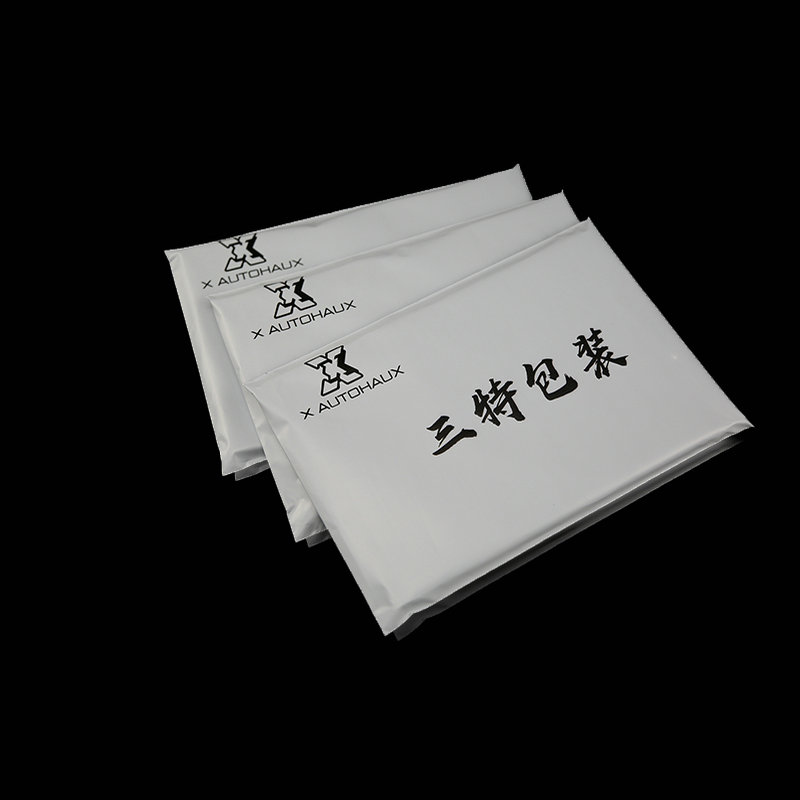

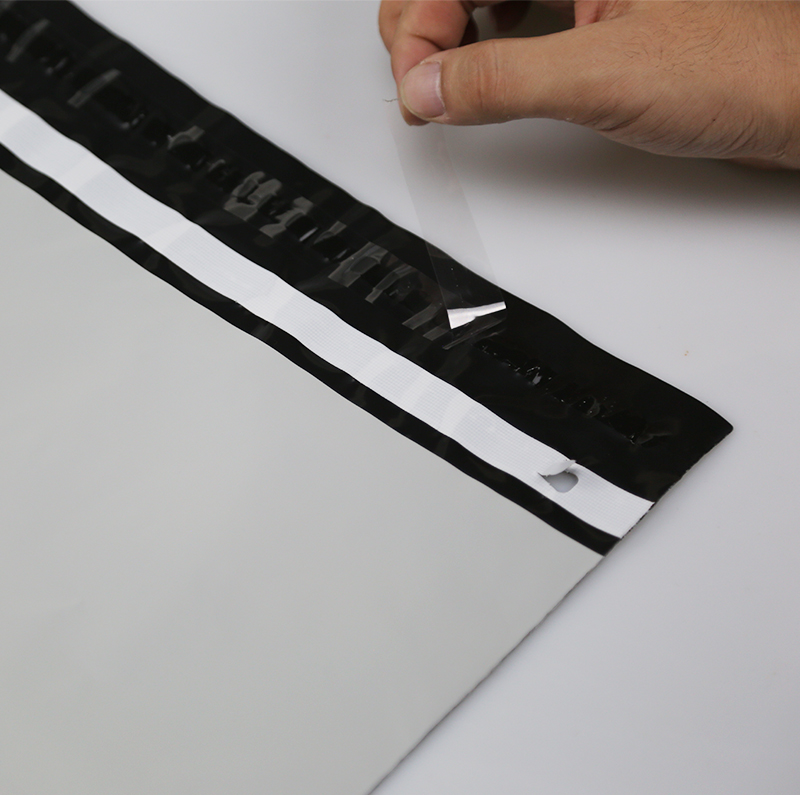

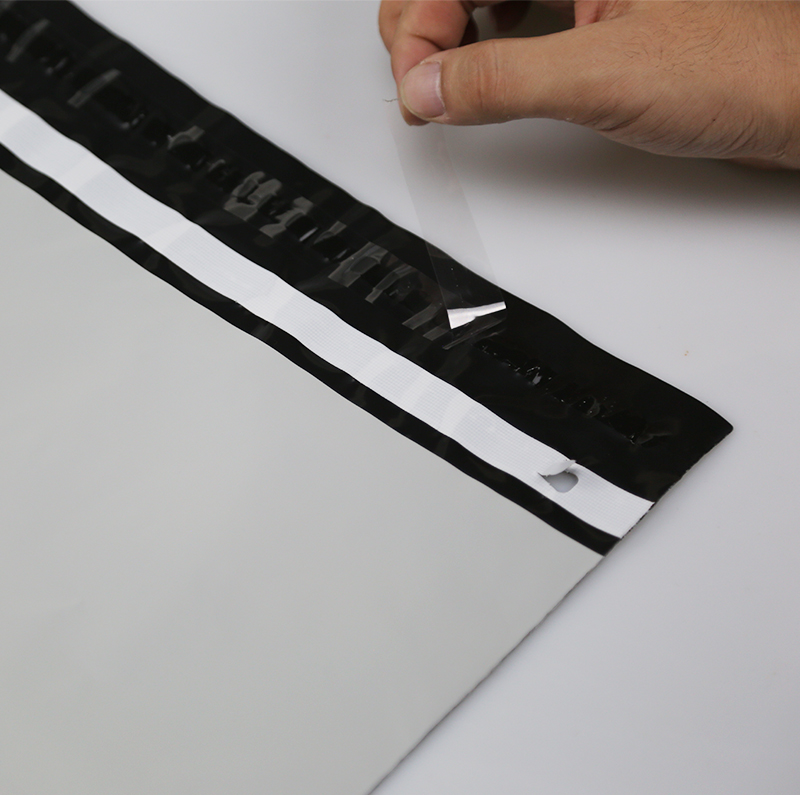

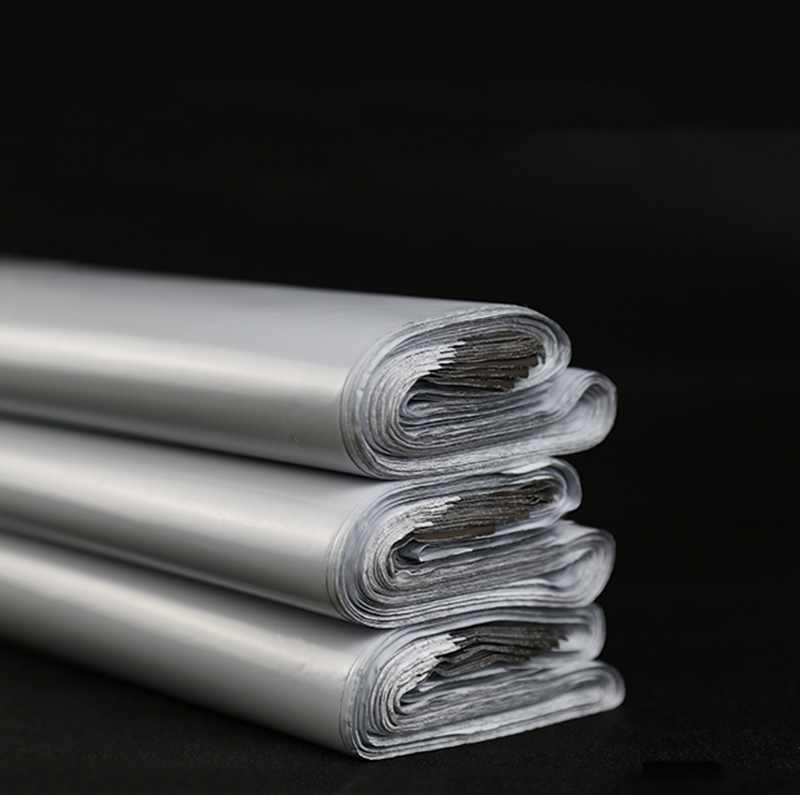

The production process of the express bag and the production process of ordinary PE bags have some difference. The express bag is characterized by inner black. It is used as a double-layer co-extrusion of yin and e-and-ectochemical injection. At present, the express bag is generally used in 3 layers. The inner layer is black, the intermediate layer is gray, the outer surface is transparent color, the three-layer co-extrusion, and strong tear resistance. The glue bag is adopted is destructive adhesive, once the courier bag is sealed, consider the warming, anti-theft function, the rubber bag of the rubber bag, using high strength rubber stick, the express bag is open, Easy torn strip joints are torn, and cannot be brought to use twice. Express adhesive bag Material: Low density polyethylene (LDPE) generally said PE, high-density polyethylene (HDPE) generally said PO, express rubber bag has a low cost, light weight and other advantages

The difference between PE and PO in the express rubber bag: PE transparency, softness is better, printing color is bright; PO has a relatively good mechanical properties; all use PE as main materials in the domestic express bag, and foreign use PE, PO composite as a main material as a courier bag

題-6.jpg)